Cabin Comfort Materials

Browse Our Expanded Collection of Aircraft Foams, Insulation, FR Fabrics and More

OmnAvia’s expanded range of cabin comfort materials offers a complete collection of foams, FR fabrics, insulation blankets and other materials to create a cabin environment that is safe, comfortable and quiet for every type of aircraft. All these materials are illustrated in our Behind the Seams catalog, a comprehensive array of products that address nearly every application that a completion or refurbishment center needs to create the ultimate cabin environment.

Our New Behind The Seams catalog features samples and specifications of a wide range of foam products for:

- Seating

- Panel coverings

- Sound attenuation

- Carpet underlayment

To download a PDF of Behind the Seams

CLICK ON THE BOOK!

SEATING FOAMS

Our OmnaFoam Platinum™ foams are graphite-impregnated aviation foams.

Our Platinum foams are graphite-impregnated aviation foams.

Platinum foams are offered in a range of firmness factors and sheet thicknesses that offer compliance with oil burner test requirements, often without a need for additional fireblock fabric encapsulation of the cushion assembly.

Included in the line-up are scrim-covered sew foams for seat cover padding or quilt stitching.

OmnaFoam Platinum™ offers compliance with the FAR 25.853(c) oil burner test in combination with most dress-covering fabrics without the need for additional “fire-blocking” materials.

Providing excellent contours and seat definition, OmnaFoam Platinum™ offers substantial improvements in physical characteristics and reductions in weights on most cushion designs.

The high-resilient nature of graphite allows for a denser cushion built at a lighter weight.

Utilizing graphite-filled foams, you can now build extremely comfortable cushions that can decrease an aircraft’s typical fuel consumption.

Graphite’s increased thermal capacity transforms our seating foams to be inherently flame retardant.

These foams can be used with or without fire-blocking fabric and still pass FAA/EASA testing requirements.

Maintaining maximum comfort at a lighter weight, the OmnaFoam Platinum stands out among the rest for providing excellent contours and seat definition. The foams are graphite-filled to ensure extraordinary durability. The graphite’s natural thermal capacity works to transform the foam to be fundamentally flame retardant.

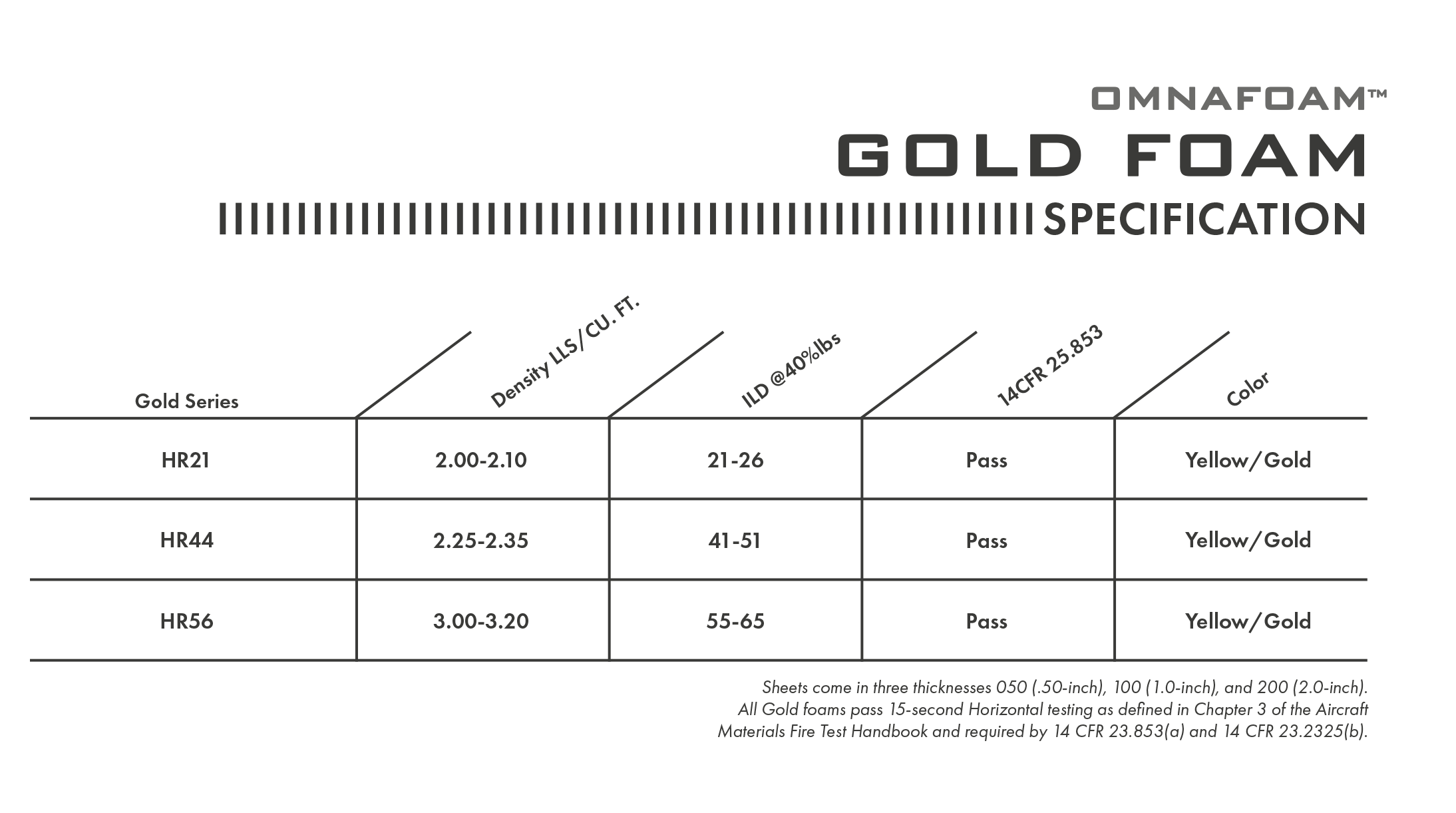

OmnaFoam Gold Foams

OmnaFoam Gold is comprised of high-resilience polyurethane (HRPU) — ideal for small aircraft, marine, or automotive applications. Maintaining compliance with horizontal burn testing, OmnaFoam Gold delivers comfort and durability for your transportation systems. It is available in three thickness levels to match your customization preferences.

OmnaFoam Carpet PADding & PANEL COVERING

OmnaFoam padding foams offer superior added comfort under a decorative material to enhance passenger experience. These foams are compliant with a 12-second vertical burn at ½-inch thickness or when tested as an assembly with a compliant panel. Thickness less than ½-inch is compliant with a 15-second horizontal burn as an independent article.

OmnaLite padding is versatile and multifunctional for carpet padding, soft touch panel padding, and localized vibration absorption. This padding is suitable for general aviation, private aircraft as well as marine and automotive uses.

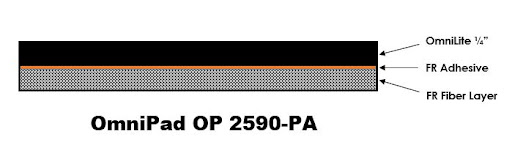

OmnaPad Carpet Padding is a luxurious underlayment for any cabin carpet that enhances the comfort of the cabin. The cushioning transforms your cabin into a private retreat with sound-dampening performance.

OmnaPad™ OP2590-PA carpet padding provides cushioning, thermal insulation, fire protection and sound dampening all in one product. It meets 12-second vertical burn requirements.

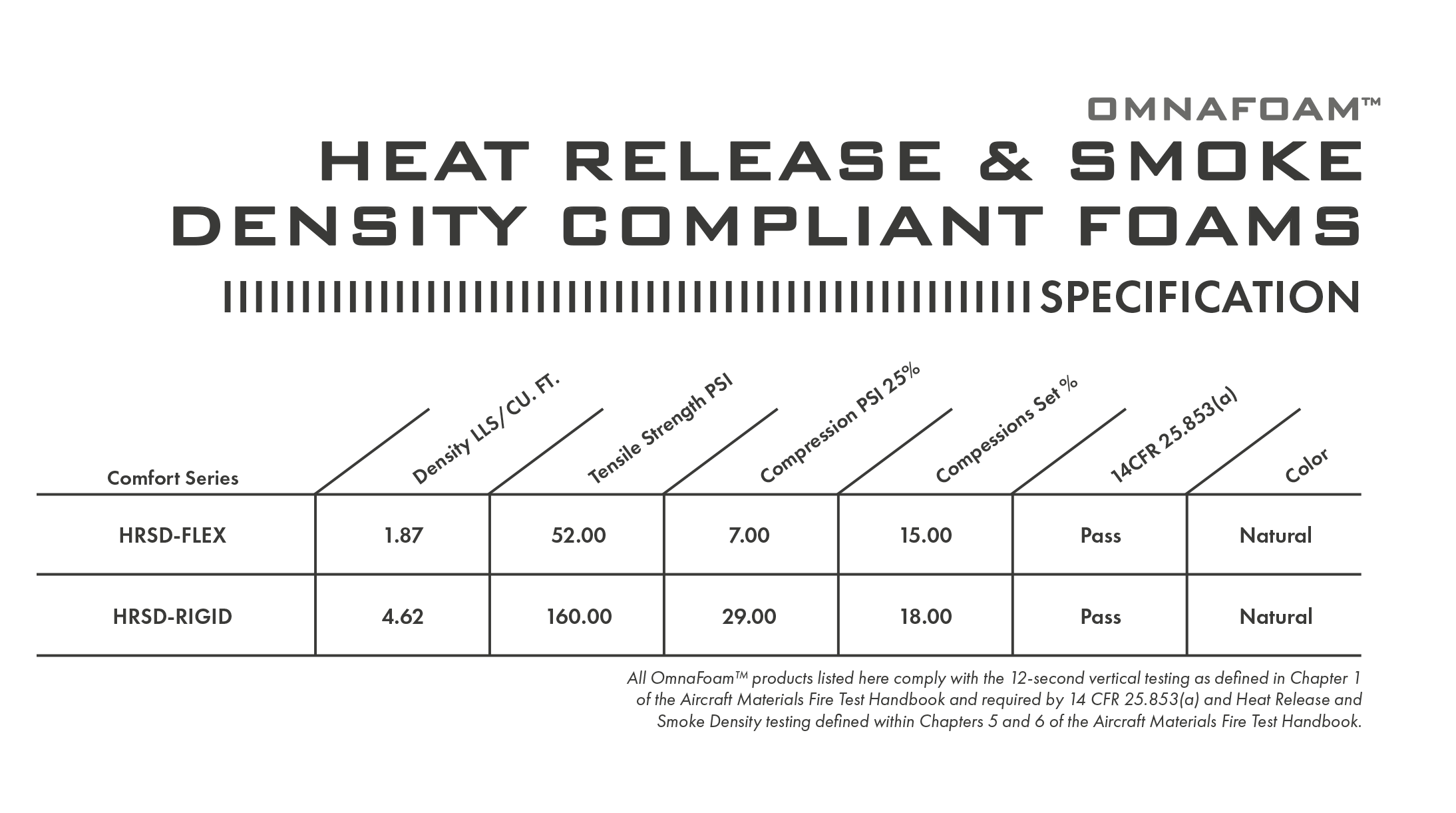

OmnaFoam HRSD foams are available to be used in the paneling of the aircraft for multiple purposes, such as softening the decorative material or reducing the noise caused by the panel’s vibrations.

OmnaFoam HRSD meets the flammability requirements of heat release and smoke density testing and is safe for use in aircraft paneling.

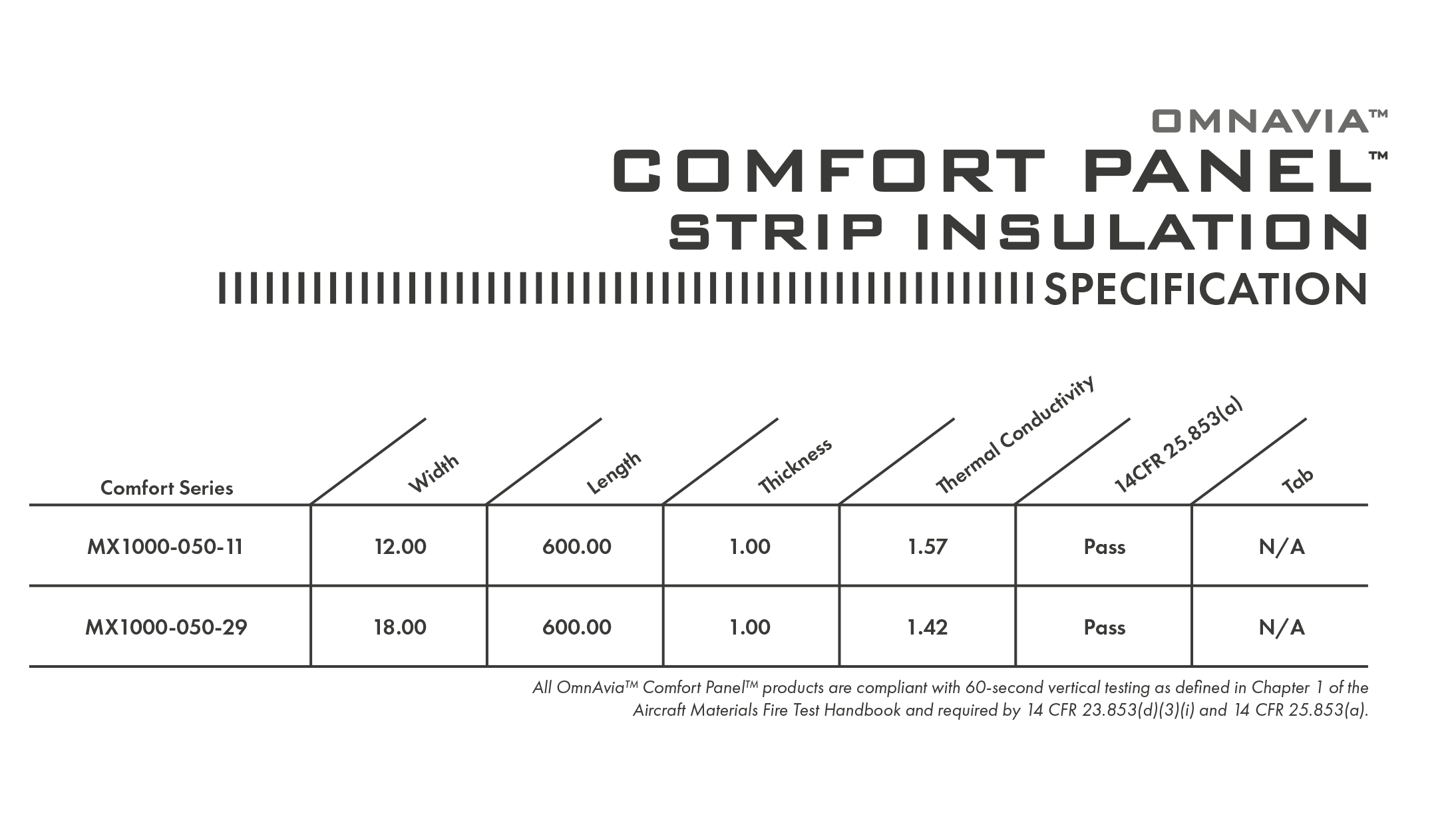

Insulation Solutions

Strip insulation in the aircraft is used to insulate the cabin from environmental conditions during regular operation. This insulation supports noise attenuation, as well. The assemblies are manufactured from batting materials with sewn or bonded skin on each side. The insulation is often applied to the inside of the aircraft skin between the skin and the outer wall of the cabin interior.

Request your sample kit of OmnaFoam today

The kit will include samples of the full range of OmnaFoam products.