Signature Plating

With more than two-decades of tradition providing superior products and outstanding customer service,

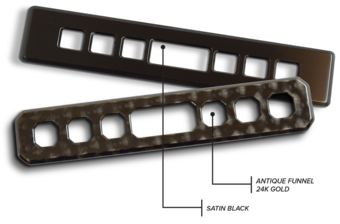

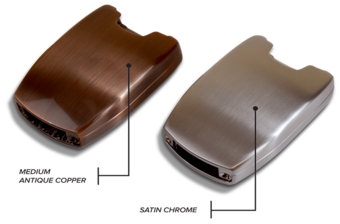

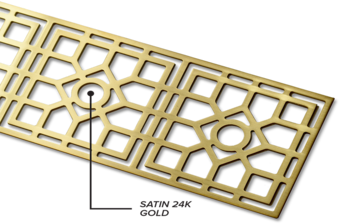

Signature Plating was founded in January 2002 to fill a void in the plating industry. Signature Plating has a full anodizing line in addition to providing an ever-growing collection of fine plating finishes, ranging from basic nickel, copper, and traditional bluechrome to exotic black and 24k gold finishes inclusive of almond, rose, blush, champagne, smoke, and midnight with the option to finish each in a polished, satin, matte, pearlite, frosted or funnel look.

The Signature Difference

Signature Plating’s equipment, technology and procedures are based on extensive industry research and practices recommended by our team of experts, considered to be the best in the industry. We offer:

- A dedicated team of professionals with more than 250 years of combined experience

- The highest-quality decorative plating in the industry

- The highest standards for manufacturers

- The ability to coordinate, and/or stock parts, for other project suppliers’ products and services to improve lead time

- A commitment to complete customer service satisfaction

A full-service plating facility, Signature Plating is dedicated to producing the highest quality products with rapid turn times that meet even the most stringent deadlines. Beyond aviation, our decorative plating services include: marine plating (yacht interiors) and custom home decor (interior decorative hardware)

Products and services

- Custom Specialty Finishes

- Polishing

- Clear Coat

- Engraving

- Anodizing Finishes

- Hassle-Free Purchase Order System

- Parts Manufacturing

- Plastics Plating

2 Panels

24K Gold

Buckles

Chrome Round

Gold Faucet

Gold Panel Cropped

Control panel in antique silver